Take a look through our sawn stone paving products and you soon realise there's a multitude of natural stone finishes on offer. Whereas some stone is purely sawn, others are sawn and sandblasted, flamed or brushed. Here's a quick run-down of what gets done and why.

Sawn stone, pure and simple

Sawn stone, such as the Beige Sandstone and Britannia Buff Yorkstones, are those which need no additional finish. This is because they have a natural slip-resistance, cut so cleanly that saw-marks are not an issue, and look gorgeous just as they are.

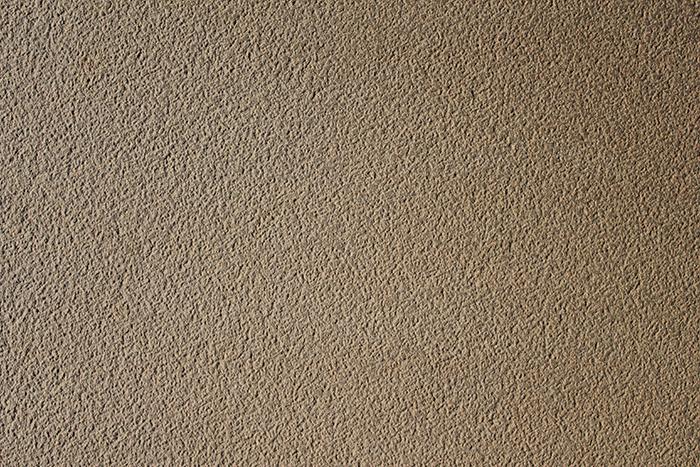

Sawn and sand-blasted

This is the one of the commonest natural stone finishes you'll come across. When natural stone paving is sand-blasted, it often indicates that it's particularly dense. If the sawn surface were not sand-blasted, it would be too smooth and slippery, especially in the wet. With it, you get a safe, non-slip surface with a very consistent texture, as illustrated below by our Buff Sawn Sandstone.

Sawn and flamed

For similar reasons, some stones are flamed. Again, this adds a non-slip finish to paving that would otherwise prove slippery, such as Flamed Grey Sandstone. However, flaming also adds an extra dimension to a stone's appearance and is particularly suitable for granites and basalt because it emphasises the crystalline structure of the material.

Sawn, sand-blasted and brushed

Brushing – which is performed with a rotating brush head, rather than an eager man with a broom – can be brought into play after sand-blasting, and is for aesthetic purposes. We do this with, for example, Jura Beige Limestone because it brings out the colour and softens the sand-blasted finish slightly, adding an aged effect.

Sawn and honed

Honing is sometimes performed for the same reason as brushing—it brings out the colour of some stones. In most cases, though, it's employed to remove saw-marks and smooth the finish.

Acid-washed

Acid-washing is a surface treatment that adds a textured and weathered appearance, increasing the sense of age. While acid cleaners are never recommended for limestone paving, a carefully controlled acid wash can give some varieties added charm. It's applied to our Acid-Washed Egyptian limestone and Antique Egyptian limestone paving options, where it enhances their natural colour variations, bringing out the pastel colours in the beige stone and the fossil markings.

You'll find information on the applied surface finish of our sawn natural stone in the Specifications section of each smooth paving product page.

Post updated February 2025.

/filters:quality(40)/mediadev/media/homepage/price_right_arrow.svg)

/filters:quality(60)/mediadev/media/menu-pics/menu_banner_mobile.png )

/filters:quality(60)/mediadev/media/menu-pics/all-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/luxury-italian.jpg )

/filters:quality(60)/mediadev/media/menu-pics/premium-italian.jpg )

/filters:quality(60)/mediadev/media/menu-pics/budget-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/large-format-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/wood-effect-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-planks.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-setts.jpg )

/filters:quality(60)/mediadev/media/menu-pics/browse-all-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/interior-tiles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-effect-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/wood-effect-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/grey-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/beige-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/dark-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/light-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/patio-grout.jpg)

/filters:quality(60)/mediadev/media/menu-pics/primers.jpg)

/filters:quality(60)/mediadev/media/menu-pics/porcelain-blades.jpg)

/filters:quality(90)/mediadev/media/menu-pics/drainage.jpg)

/filters:quality(60)/mediadev/media/menu-pics/cleaners.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-stone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-sawn-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-riven-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/indian-sandstone.jpg )

/filters:quality(60)/mediadev/media/menu-pics/limestone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/granite-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/slate-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/cobbles-setts.jpg )

/filters:quality(60)/mediadev/media/menu-pics/plank-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/paving-circles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-paving-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/edging-stones-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/prestige-stone.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-blue-stone.png)

/filters:quality(60)/mediadev/media/menu-pics/swatch-black-dark.jpg )

/filters:quality(60)/mediadev/media/menu-pics/swatch-buff-beige-white.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sealants.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-clay-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/alpha-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/cottage-garden-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/kessel-garden-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/artisan-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-blue-clay-paver.png )

/filters:quality(60)/mediadev/media/menu-pics/red-brown-clay-pavers.png )

/filters:quality(60)/mediadev/media/menu-pics/beige-buff-clay-pavers.png )

/filters:quality(60)/mediadev/media/menu-pics/composite-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/designboard-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/classic-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/brushed-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grooved-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/millboard-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/black-charcoal-decking.jpg)

/filters:quality(60)/mediadev/media/menu-pics/brown-decking.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-build-deck.png )

/filters:quality(60)/mediadev/media/menu-pics/stone-cladding.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-garden-walling-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/facing-bricks.jpg )

/filters:quality(60)/mediadev/media/menu-pics/garden-screening.jpg )

/filters:quality(60)/mediadev/media/menu-pics/menu_Garden_banner_desk.png )

/filters:quality(60)/mediadev/media/menu-pics/all-steps-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-garden-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sawn-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/riven-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/off-the-shelf.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sawn-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/riven-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-pier-caps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-bespoke-services.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-paving-2.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-steps-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-coping-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/edge-profiles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/masonry-services.jpg )

/filters:quality(60)/mediadev/media/menu-pics/deluxe-pergolas.jpg )

/filters:quality(60)/mediadev/media/menu-pics/proteus-pergolas.jpg )

/filters:quality(60)/mediadev/media/menu-pics/corten_planter_menu.png )

Trade Discount Available

Trade Discount Available FREE Nationwide Delivery

FREE Nationwide Delivery Nationwide Showrooms

Nationwide Showrooms Live Stock Levels

Live Stock Levels Split Packs Available

Split Packs Available