Our digital laser templating service makes a project easier by taking a load of work and responsibility from your shoulders. We look at how it works.

Do you need laser templating?

If you’ve ever made a costly mistake—cut paving and then realised you’ve mis-measured a gap, or provided templates and realised that you'd forgotten to add the overhang to steps—then you know the waste of time and materials involved.

Or perhaps you need paving, steps or coping for a complicated site with multiple levels, curved edges and awkward corners, or just an odd-shaped piece that’s going to be the devil to cut. There are so many projects that use digital laser templating.

Digital laser templating—where our experts visit, measure the required areas with pinpoint accuracy and then translate the layout into CAD design for precise cutting on a CNC machine—cuts out the headache and removes the risk of any mistakes. As we'll see, it can also work out cheaper than creating your own templates.

What happens when we laser template your site

Photo request

Before visiting, we may ask you to send images of the current state of the site.

Images will tell us if it’s too early for a site visit We don’t want to waste your time and money with an unnecessary visit. In the project below, for example, it was an easy decision for us to hold off until all the concrete substrates were in place.

This next project was ready for templating, with the edge of the bricks as a reference point. From these measurements, a 40mm overhang was added for the bullnose step tread and gaps allowed between brickwork and stone for perfect fitting.

The site visit

When we arrive, we'll scan the site with our digital laser templating equipment. Depending on what’s required we may be anything from less than an hour to several hours on site. The survey below, to template a swimming pool, took only 45 minutes.

Once our operative Akif Akif set up the laser, he followed the edge of the pool and took measurements all the way round in approximately 300mm increments. Any edges the laser couldn’t hit, Sonny Simmonds was on hand with a timber batten or marker pads, so the laser could hit the right spot to capture the measurement.

CAD drawings created

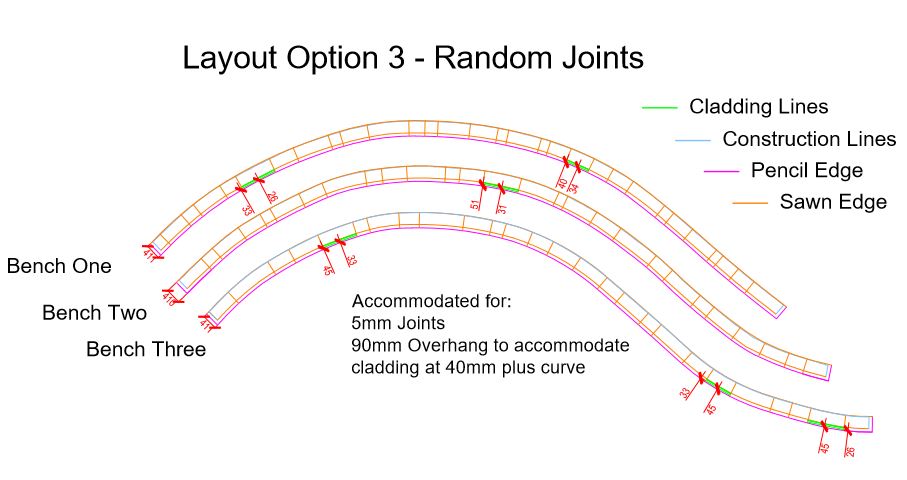

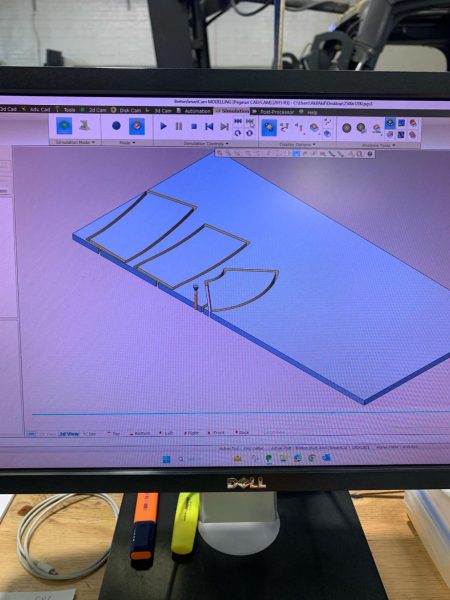

Back at our Bespoke Stone Centre, we look at the outlines that have been scanned and determine the best way to set out the templates. Skill and knowledge are vital at this stage, when overhangs, riser height, cladding and joint widths need to be factored into the measurements. Some clients require segments on curves to be identical, which demands detailed working so that the radius of each segment looks comfortable.

In the project above, Nik Edser of Langdale Landscapes wanted random segments, which made the cuts easier to place. The result is the Cut Sheet which shows all the individual segments.

Plans sent to client

We discuss matters with the client as we progress, to keep the client fully and ensure all parties are happy with the stone placement.

Drawings typically take around two weeks to complete. Once the client’s chosen the drawings they want, a DXF file is created of each item. These inform the CNC machine of the shapes required to produce the solid pieces.

Templates produced

The templating information and drawings are produced and sent to the customer for approval. This is also when the number of templates required is agreed. When all is approved, the templates are then scheduled for production on our CNC machinery.

Digital laser templating for peace of mind

You can see the results of expert digital laser templating in pictures of the finished projects. Lser templating takes the anxiety out of getting every cut right, as we at London Stone take full design responsibility for ensuring that everything fits together as intended.

What we can't laser template

Not every situation is possible to laser template. The wall above is a case in point. The wall curves and descends at the same time, so our templater would read the outline incorrectly and produce an inaccurate drawing. This is why it's important to give us all the detail and photos where possible.

Digital laser templating saves money

Bringing in our laser templating service is like an insurance policy, protecting you from costly mistakes, while creating really accurate lines and offering you complete peace of mind.

The final cost includes site visits and the charge for each template. What surprises some landscapers is that laser templating can be cheaper than sending us plywood templates. It saves you time, as well.

The laser tends to be much more accurate over wood that’s been shaped with a Stanley knife, when a steady hand is needed. Also, because we use water to cut the stone, wooden templates create difficulties with water absorption which distorts the shape, so we tend to laser template a wooden template in-house.

This extra work means that it’s often cheaper to go to the site, and infinitely more accurate to use a laser template for a truly professional finish.

The next step

Be inspired by some of the projects which used our digital laser templates.

Or get in touch to discuss how digital laser templating can help with your project.

/filters:quality(40)/mediadev/media/homepage/price_right_arrow.svg)

/filters:quality(60)/mediadev/media/menu-pics/menu_banner_mobile.png )

/filters:quality(60)/mediadev/media/menu-pics/all-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/premium-italian.jpg )

/filters:quality(60)/mediadev/media/menu-pics/budget-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/large-format-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/wood-effect-porcelain.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-planks.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-setts.jpg )

/filters:quality(60)/mediadev/media/menu-pics/browse-all-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/interior-tiles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-effect-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/wood-effect-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/grey-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/beige-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/dark-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/light-porcelain.png )

/filters:quality(60)/mediadev/media/menu-pics/patio-grout.jpg)

/filters:quality(60)/mediadev/media/menu-pics/primers.jpg)

/filters:quality(60)/mediadev/media/menu-pics/porcelain-blades.jpg)

/filters:quality(90)/mediadev/media/menu-pics/drainage.jpg)

/filters:quality(60)/mediadev/media/menu-pics/cleaners.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-stone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-sawn-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-riven-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/indian-sandstone.jpg )

/filters:quality(60)/mediadev/media/menu-pics/limestone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/granite-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/slate-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/cobbles-setts.jpg )

/filters:quality(60)/mediadev/media/menu-pics/plank-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/paving-circles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-paving-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/edging-stones-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/prestige-stone.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-blue-stone.png)

/filters:quality(60)/mediadev/media/menu-pics/swatch-black-dark.jpg )

/filters:quality(60)/mediadev/media/menu-pics/swatch-buff-beige-white.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sealants.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-clay-paving.jpg )

/filters:quality(60)/mediadev/media/menu-pics/alpha-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/cottage-garden-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/kessel-garden-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/artisan-clay-pavers.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-blue-clay-paver.png )

/filters:quality(60)/mediadev/media/menu-pics/red-brown-clay-pavers.png )

/filters:quality(60)/mediadev/media/menu-pics/beige-buff-clay-pavers.png )

/filters:quality(60)/mediadev/media/menu-pics/composite-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/designboard-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/classic-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/brushed-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grooved-designboard.jpg )

/filters:quality(60)/mediadev/media/menu-pics/millboard-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/grey-decking.jpg )

/filters:quality(60)/mediadev/media/menu-pics/black-charcoal-decking.jpg)

/filters:quality(60)/mediadev/media/menu-pics/brown-decking.jpg)

/filters:quality(60)/mediadev/media/menu-pics/all-build-deck.png )

/filters:quality(60)/mediadev/media/menu-pics/millboard-cladding.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-cladding.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-garden-walling-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/facing-bricks.jpg )

/filters:quality(60)/mediadev/media/menu-pics/garden-screening.jpg )

/filters:quality(60)/mediadev/media/menu-pics/menu_Garden_banner_desk.png )

/filters:quality(60)/mediadev/media/menu-pics/stone-garden-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sawn-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-steps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/sawn-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/yorkstone-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/porcelain-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/stone-pier-caps.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-coping.jpg )

/filters:quality(60)/mediadev/media/menu-pics/all-bespoke-services.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-paving-2.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-steps-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/bespoke-coping-1.jpg )

/filters:quality(60)/mediadev/media/menu-pics/edge-profiles.jpg )

/filters:quality(60)/mediadev/media/menu-pics/masonry-services.jpg )

/filters:quality(60)/mediadev/media/menu-pics/deluxe-pergolas.jpg )

/filters:quality(60)/mediadev/media/menu-pics/proteus-pergolas.jpg )

/filters:quality(60)/mediadev/media/menu-pics/corten_planter_menu.png )

Trade Discount Available

Trade Discount Available FREE Nationwide Delivery

FREE Nationwide Delivery Nationwide Showrooms

Nationwide Showrooms Live Stock Levels

Live Stock Levels Split Packs Available

Split Packs Available